SCZP-1300 Triple-SERVO slitter

Main cutting machine:

Power: 15KW

Material width: 1300 mm

Material diameter: 800 mm mm

Winding diameter: 600 mm mm

Paper tube hole: 3# 6#

Cutting speed: 10-400 m/min

Correction accuracy: ≤0.1mm

Minimum cutting width: 30mm

Weight: 3000KG

Main slitting machine size: L 3200mm*W 2200mm*H 2000mm

Classification :

Keywords :

SCZP-1300 Triple-SERVO slitter

PRODUCT DETAILS

Keywords: Qingdao Weidongli

Technical specification

Main cutting machine:

Power: 15KW

Material width: 1300 mm

Material diameter: 800 mm mm

Winding diameter: 600 mm mm

Paper tube hole: 3# 6#

Cutting speed: 10-400 m/min

Correction accuracy: ≤0.1mm

Minimum cutting width: 30mm

Weight: 3000KG

Main slitting machine size: L 3200mm*W 2200mm*H 2000mm

Note:

1. The price is FOB (Ningbo China), including delivery fee to Ningbo China port, with customs clearance.

2. Payment method: T/T wire transfer. 30% of the total amount should be paid in advance, and the remaining balance should be paid before shipment.

3. Packaging: export standard wood packing.

4. Warranty: the whole machine for one year (except maintenance spare parts).

5. Complete production within 30 days after receiving 30% deposit.

6. Delivery time: (after completion of production) after receiving 100% payment, 10 working days to the forwarder.

7. The Seller not responsible for send engineer to buyer factory for assisting the buyer in the installation and commissioning of the new slitting machine.

But video call to assist after-sales service in a reasonable time to the buyer is responsible.

8. Validity period: The offer is valid for 30 days.

(PS: If you have additional needs for slitter rewinding machinery, please let us know, thank you.)

One、Unwinding section

1、3 inch or 6 inch shaft-less integrated pneumatic cone tops are adopted for unwinding, manual pulling is needed for locking and positioning.

2、Cylinders/Hydraulic control feeding plates as they go up and down.

3、standard machine with magnetic powder to control unwind jumbo roll tension. They detect roll diameters automatically, and automatically stops if feeding is cut off or no feeding is

detected.

4、Feeding plates are equipped with automatic alignment systems, and the alignment point can be in accordance with inner printed edge or material outline.

5、The Unwinding diameter is 800mm.

Two、Traction section

1、A 120mm diameter mirror traction roller.

2、The traction roller power is 5.5 KW Converter SERVO, TAIWAN FUKUTA BRAND and it is driven by two synchronizing wheels of two proportions. They increase the rotation speed of motor,

thus reduce electrical cost.

3、Equipped with a 120mm passive pressing rubber roller and automatic pressing device.

Three、Rewinding section

1、It adopts two 3 inch slip shafts to rewind.

2、It uses 2 sets of 3.7kw converter SERVO (motors), TAIWAN FUKUTA brand to drive rewinding.

3、The upper and lower shafts are equipped with pressure rollers to make the material winding smooth.

4、The pressure roller maintains a constant pressure, which is controlled by a precise pressure regulating valve.

5、It has 10 laser lights guid beam positioned infrared paper tube.

6、The speed of this machine is 10 to 400m/minute.

7、The maximum rewinding diameter is 600mm.

Four、Slitting section

1、10 straight blades or round knives

2、The cutter shaft automatically lifts and lowers the knives.

3、The slitting width is 30-1300mm.

Five、Unloading section

1、A set of Auto Rotary unloading Device.

2、Include a waste edge trimming winder.

3、With auto pusher for finished rolls unloading.

Six、Device configuration

|

Parts Name |

Style |

Quantity

|

Brand |

|

Machine wallboard |

40mm/Thick 40mm |

1 set |

|

|

Rewinding shaft |

3 inch slip shaft |

2 pieces |

30mm |

|

Maintraction roller(mirror surface) |

120mm*1400mm |

1 piece |

|

|

Rubber pressing roller |

120mm*1400mm |

1 piece |

|

|

alumina guide roller |

90mm*1400mm |

6 pieces |

|

|

Unwinding |

5.5kw SERVO |

set |

FUKUTA Taiwan

|

|

Tension control motor |

SERVO motor |

1 set |

FUKUTA Taiwan

|

|

Rewinding motor |

3.7kw SERVO |

2 sets |

FUKUTA Taiwan |

|

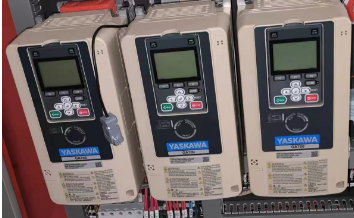

Converter |

3.7kw/5.5kw |

2 units/1 unit |

YASKAWA Japan

|

|

Edge blowing machine |

1.5KW |

1 unit |

Normal motor |

|

Bearings |

|

1 batch |

NSK Japan |

|

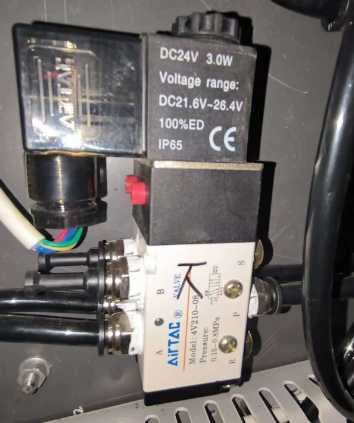

Pneumatic components |

|

1 batch |

Airtac Taiwan

|

|

Web guide Analog alignment |

|

1 set |

Pausource Taiwan

|

|

PLC |

Germany Siemens

|

1 |

|

|

10 inch touch screen |

|

1 |

WEINVIEW |

|

Proximity switch |

|

1 |

Japan |

|

Low voltage electrical apparatus |

|

1 batch |

Schneider French |

|

Switch power supply |

|

1 |

Japan |

|

Precisionpressure regulating valve |

|

4 |

Airtac Taiwan

|

|

Linear guide rail |

HBR35 |

1 set |

Taiwan |

|

Laser lights |

|

10 |

Domestic |

Packaging and shipping

We have core patented technologies in the expansion shaft, with precision production quality, advanced production technology and perfect testing equipment. The company also has a strong technical service team ready to solve relevant technical problems for you at any time, so that you can have no worries about product selection.

EQUIPMENT

We have core patented technologies in the expansion shaft, with precision production quality, advanced production technology and perfect testing equipment. The company also has a strong technical service team ready to solve relevant technical problems for you at any time, so that you can have no worries about product selection.

FACTORY WORKSHOP

VIDEO

FAQ

Q1: Are you a manufacturer?

Q2:Can we visit your factory ?

Q3: How long is your delivery time?

Q4:How can we get the offer?

Q5:Can we get the some samples?Any charges?

Q6: How do you make our business long-term and good relationship ?

RELATED PRODUCTS

GET A FREE QUOTE